Hardwood flooring brings richness and warmth to a room that cannot be matched by carpet, vinyl, or linoleum. It provides a durable surface that will hold up very well over time with little maintenance. To make sure you install the proper hardwood, examine the different types of hardwood floors. Consider factors such as floor construction, wood specie and finish, and color of the hardwood, because these choices will greatly affect the appearance and performance of the floor. Deciding what type of environment is desired in the room will help you choose which type of hardwood floor will best fit your needs.

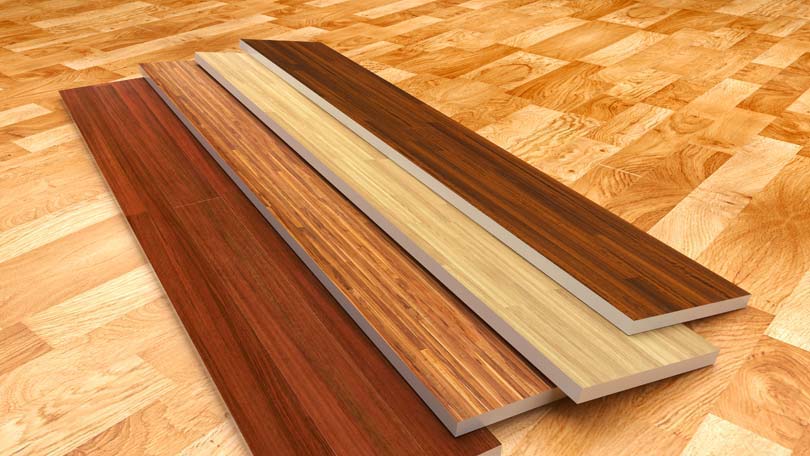

First, hardwood floors come in three different construction options: solid, engineered, or longstrip. Solid wood floors are quite common and have been installed for years in many homes. Most solid hardwood floors are a 3/4” thickness and come in 2 ¼” strips. The solid wood planks are cut directly from a tree, and then manufactured into planks with tongue and groove ends. Sometimes the solid floors are finished in the factory, or they can be left unfinished for the buyer to seal and stain.

Because solid wood is susceptible to water damage it is not recommended for use in a basement or for installation over a concrete subfloor. They can be installed on the ground level or any level above. The most commonly used solid wood species are maple, ash, red oak, and white oak, but other exotic species are available. Of those, maple and white oak are the hardest; hardness can be equated to a floor’s ability to resist denting or chipping while under pressure.

Engineered wood floors (different from laminate flooring) are thin sheets of wood known as veneers that are pressed, heated, and glued together to form a single plank. Thickness of these floors can range from ¼” to 9/16,” and width ranges from 2 ¼” to 7.” When the engineered floors are made, three to seven veneers are stacked on top of each other with every other piece placed in opposite directions. This helps to make the engineered wood resistant to expansion and contraction as wood always wants to expand one way. Because the veneers are placed in opposite directions (cross-ply construction), the finished plank is dimensionally stable; it can be used on concrete slabs or in basements. Also, the top piece of wood can be made of any wood variety and will be less expensive than a solid wood plank from that same wood species. Engineered floors can be nailed down, stapled, glued, or floated, and are all prefinished by the manufacturer.

Longstrip wood floors are very similar to engineered floors, but are made of only three layers. The center of a longstrip is a softer wood that is manufactured to have tongue and groove edges. A chosen wood specie is glued over the top of the softer core (usually the top layer is a harder wood), and another softer wood layer is glued onto the bottom of the core. The top layer of wood is actually made of smaller wood planks laid three strips wide and 17 to 18 strips long (hence the name – longstrip). One piece of longstrip is usually 7 ½” wide and 86” long.

Longstrip wood floors take a little less time to install because they come as bigger pieces, and are stable like engineered floors so they can be placed in a basement or over concrete subfloors. They can be used over radiant heat systems as well. With tongue and groove construction, most longstrips can be installed as floating floors (without glue, nails, or staples), but they can be glued or stapled if necessary. Longstrip floors are finished by the manufacturer.

Quite recently, manufacturers of hardwood floors have developed a way to apply extremely durable urethane finishes at the factory. They use ultraviolet lights to apply numerous coats of the urethane finish very quickly, and some companies have begun to add aluminum oxide to the floors to increase the life of the finish. The result is a very high quality, heavy-duty finish. For customers that desire a custom stained hardwood floor, unfinished floors are a way to provide just that. Unfinished floors must be sanded, stained, and finished after installation. Water, oil-based, or moisture cured urethane can be applied as finish, and each of those come in a variety of colors.

Different types of hardwood floors will influence the atmosphere of a room – pine flooring (one of the softest hardwood floors) may be best suited for a cabin or cottage as it gives a rustic, rugged sort of look. Oak flooring is much harder (and more expensive) and will provide a more elegant and refined look. There are over twenty types of wood species to choose from, so factor in hardness, cost, and desired ambiance of a room before ordering.